100 Set(s) (MOQ)

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Importer |

| Water Lubricated Size Range | 2.5 Inch to 8 Inch |

| Large Capacity Range | From 10 to 500 M3H or 50 to 1500 IGPM |

Vertical Turbine Borehole Pumps :

- High Efficiency

- Easy to Install and Dismantle

- Minimum Maintenance Costs-no Attention Required Whilst Pump is Running

- Driving Power Requirements are Reduced to a Minimum

- All Parts are Replaceable

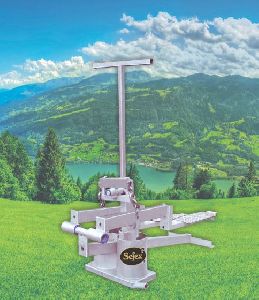

The Discharge Head

The Sefex drive and discharge head is made from high grade cast iron and it is mounted at the top of the borehole or well. The head carries all the column pipes which are linked through the head to its horizontal discharge outlet. Inside the discharge head a generous area is provided to allow easy flow of water - this also helps to reduce friction losses to a minimum.

The head shaft passes through the whole depth of the head and is connected to the line shafting which transmits the rotary drive to the impellers. Lubrication of the bearings in the discharge head is effected by periodical injection of grease or circulation of oil. The stuffing box is conveniently located in the head and is easily accessible for servicing.

Adjustments to the impeller are made by means of a regulating nut on top of the head. A non reversible type pulley is fitted dowels block any reversal motion as soon as the pump stops rotation a clockwise direction.

The construction of the head allows various alternative drives to be used directly coupled, flat or V-belt, and right angle gear type using flexible shaft or pulley

- Pulley

- Adjusting nut

- Boaring housing assembly

- Head frame

- Lock nut

- Head shaft

- Top bearing

- Bearing Spindle

- Bottom bearing

- Stuffing cover

- Stuffing

- Priming Funnel

The Column Stage

Each stage includes :

One part with two forged and machined flanges welded on each end. The pipe is of standard length (2.5 m or 3m according to customers Requirement)

A top quality stainless steel transmission shaft, ground and polished and tested for perfect straightness so that it ensures minimum vibration and longer bearing life.

The shafts are connected by couplings. A spider bearing assembly provided with a special water lubricated rubber center bearing is bolted between the pipe flanges at intervals (2.5 m or 3 m according to the column length) to ensure accurate concentricity and alignment of the line shaft. These bearings are primed by means of the funnel mounted on the discharge head. Priming is only necessary when the pump has been standing idle.

- Top column flange

- Spider bearing

- Column shaft

- Column Pipe

- Coupling

- Rubber bearing

The bowl assembly

This section, the HEART of the pump, is of the multi-cellular type and is always submerged below water level. Of a very practical design, it is especially suitable for narrow wells and boreholes.

The helico-centricugal type impellers are made of high grade cast iron and balanced. They are built up on an extra strong stainless steel shaft and securely locked in position by a double cone tightening systems.

A water lubricated rubber bearing is fitted into each of the bowls between the impellers - these bearings also act as stabiliser guides for the shaft.

The curve of the bowl diffusers is designer to allow water to flow freely through the bowl stages without turbulence - this reduces friction loss to a minimum and gives the maximum output.

- Top bowl

- Taper impeller cone

- Intermediary bowls

- Suction manifold

- Strainer

- Lock nut

- Bowl rubber bearings

- Impellers

- Footvalve assembly

Typical applications available:

- Semi-crossed, flat belt driven Pump- by mens of a slow speed vertical Diesel engine.

- V-belt driven Pump - powered by an electric motorl Both motor and pump are mounted on a fabricated steel base.

- Pump fitted with right angle gear drive - powered by a multi-cylinder medium speed Diesel engine. Alternatively it could be driven by an electric motor.

- A further semi-crossed, flat belt driven Pump operating on an open well-driven by a slow speed horizontal Diesel engine. (A semi-crossed V-belt could replace the flat belt).